Images

Electrolytic production

Copperpowder is a fine, powdered form of copper consisting of small copper particles.

It is widely used in metalworking, the chemical industry, and various industrial applications.

Properties of Copper Powder

• High electrical and thermal conductivity

• Good corrosion resistance

• High density

• Susceptible to oxidation (especially in fine particles)

Production

Copper powder is produced by several processes, including:

1. Electrolytic deposition – The most common process, in which copper is deposited from a solution by electrolysis and then ground into a powder.

2. Atomization – Molten copper is atomized in a high-pressure gas or water stream, creating fine particles.

3. Mechanical comminution – Copper is mechanically crushed and ground.

4. Chemical reduction – Copper compounds such as copper oxide are converted into copper powder using a reducing agent.

Uses

• Electronics (conductive pastes, 3D printing)

• Metallurgy (powder metallurgy for the production of sintered parts)

• Paints and pigments

• Antibacterial coatings

• Antibacterial coatings

• Lubrication (in high-temperature lubricants)

• Explosives and pyrotechnics

Storage- Because copper powder can be flammable in very fine form, it must be stored and processed under safe conditions.

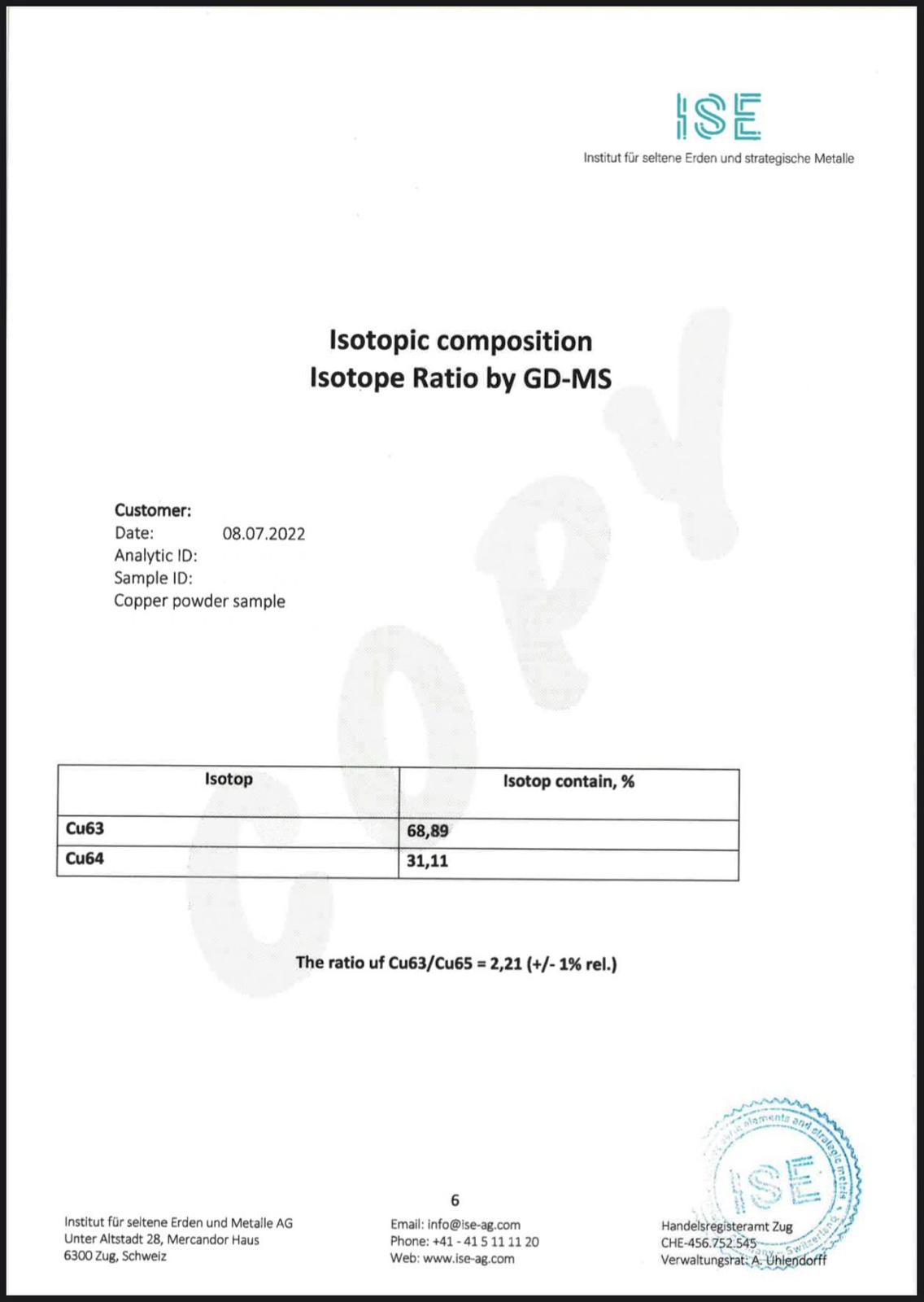

PDF Document

You can download the full Analysis PDF file below:

Download PDFYou can download the full Evaluation Report PDF file below:

Download PDF